New Stock every week - Worldwide Shipping

New Stock every week - Worldwide Shipping

DAVID FARROW - GUITAR PROJECT

January 20, 2018 3 min read 2 Comments

Inspired by the Jack Daniels guitar used by Justin Johnson, which I saw on YouTube, I decided to try something similar. The result is shown in Photos 1 and 4.

I sourced an oak Heaven Hill Whiskey barrel lid off Gumtree and an excellent Alder blank from guitarbuild.co.uk.

The barrel lid came apart easily. The individual slats were only doweled together and it was a simple matter of gently prising them apart. I sliced just over 5mm off each slat using a band saw and ran them lightly through my thicknesser/planer so that the slices were all 5mm thick. The slices were very lightly sanded and gently cleaned up with wire wool and white spirit, taking care not to remove any of the printing. They were then set aside and allowed to dry out for about four weeks.

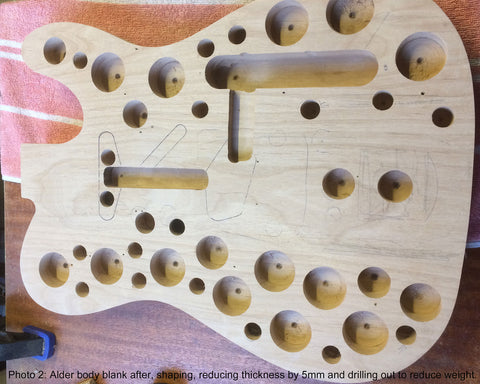

As the body blank was 44mm and I was intending to face it with the 5mm oak slices, to achieve the final guitar thickness of 44mm, obviously it was necessary to take 5mm off the alder body blank. This was done with a router on a home-made sled, taking 1mm off at a time, to ensure a smooth and flat finish. Once done, the body blank was routed to shape using a template sourced off the internet and then a series of small cavities were drilled in it to reduce the weight (see Photo 2).

Once I was happy that the oak slices had dried out, they were glued to the shaped alder body and then routed to the same shape, using the alder body as the template. The sides were then hand sanded to remove router marks and to get a consistent finish and a seamless join between the oak and the alder.

As an aside, I found that working on the barrel slices was very pleasant – there was a lovely whiskey smell every time I drilled, routed or sanded the oak!

Alder is quite white and I wanted a finish on it that came somewhere near the silver grey colour of the weathered oak of the barrel lid. The edge of the oak where it has been routed to shape, was also a lighter colour. I used the traditional wire wool in white vinegar method to achieve this, leaving the wire wool in the vinegar for two days before using it. The result is a nicely coloured back which shows up the alder grain well (Photo 3). Also the stain reacted differently to edge of the oak, turning it quite dark, which almost looks as if I have applied a binding – a happy accident! So far, I haven’t applied any finish to the face of the guitar. I like the way it looks as it is.

A Bigsby tremolo conversion kit was sourced from the USA and after much research I decided to fit the guitar with a pair of Seymour Duncan Quarter pounders.

The neck pocket, control cavity and pickup cavities were routed. The control and pickup cavities were fully lined with copper foil, which was earthed and has resulted in hardly any hum.

The guitar was completed with a bought tele neck and Wilkinson locking tuners. I have made necks from scratch in the past but frankly, I can’t be bothered with setting out and fitting the frets, so I took the easy route this time.

I’m pretty happy with the result and, happily, it plays as well as it looks, with plenty of treble and sustain.

2 Responses

Tracii Kunkel

November 13, 2018

Stunning and inspiring.

Leave a comment

Comments will be approved before showing up.

Subscribe

Sign up to get the latest on sales, new releases and more …

Les Meeking

November 13, 2018

Looks Great. Like the finish. A job well done.